How to Break-in a New RC Car Engine: Pro Guide

Breaking in a new RC car engine is an essential process that ensures the longevity and optimal performance of your nitro-powered vehicle. In this comprehensive guide, we will delve into the intricacies of how to break in a new RC car engine with expert precision.

We'll begin by discussing crucial safety tips during preparation, as well as methods for ensuring proper fuel flow and lubrication. As we progress, you'll learn about priming techniques for easier starting, monitoring temperature levels, and making tuning adjustments accordingly.

Furthermore, we'll explore various methods for breaking in an RC car engine such as heat cycling, bench break-in method, running break-in method and advanced techniques tailored to seasoned hobbyists. To ensure seamless operation throughout the entire process, our troubleshooting section will cover common problems like stalling or overheating issues while providing effective solutions.

Last but not least, maintaining your nitro engine after the break-in procedure is equally important; hence we’ll discuss regular check-ups and tune-ups along with when it's best to seek expert advice. By following this detailed guide on how to break in a new RC car engine properly, you can confidently enjoy peak performance from your prized possession while extending its lifespan significantly.

Table of Contents:

- Preparing for the Nitro Engine Break-in Process

- Testing RC Car Controls

- Starting the Engine and Initial Warm-up

- Optimizing Your Nitro RC Car's Engine Performance

- Monitoring Temperature & Tuning Adjustments

- Breaking In Your RC Car Engine: Methods & Techniques

- Troubleshooting Common Break-In Problems

- Post-Break-In Maintenance & Care

- FAQs in Relation to How to Break in a New Rc Car Engine

- Conclusion

Preparing for the Nitro Engine Break-in Process

Get ready to break-in your RC nitro engine by preparing your workspace and gathering necessary tools like an electric starter, fuel bottle with nitro fuel, spare glow plugs, and basic maintenance tools.

Testing RC Car Controls

- Cylinder Head: Check if all screws are tightened properly before running your engine during the initial stages of breaking in.

- Fuel Tank: Inspect for leaks by filling up with nitro fuel then closing off the vent line while squeezing the tank slightly - no bubbles should appear around the cap area when pressure is applied correctly.

Don't forget to read through the manufacturer guidelines provided with your new RC nitro engine to familiarize yourself with important details about its operation and maintenance requirements throughout its lifespan.

Starting the Engine and Initial Warm-up

Properly starting your RC nitro engine is crucial for a successful break-in procedure, so let's get started.

Preheating the engine

Before starting, preheat the engine with a hairdryer or heat gun to relieve cylinder pinch and ensure smooth operation during startup.

Priming techniques

Prime the engine by placing a finger on the carb inlet while pulling on the starter cord or using an electric starter with a primer button to allow fuel flow into the carburetor.

Ensuring correct transmitter/receiver setup

- TIP: Always turn on the transmitter first followed by the receiver to prevent unwanted movements due to signal interference.

- Make sure both transmitter and receiver are switched on correctly before using a glow plug igniter.

Remember to use nitro fuel and half throttle during the break-in procedure, and keep an eye on the cylinder head and engine cool to ensure proper operation.

Optimizing Your Nitro RC Car's Engine Performance

Running your nitro engine at varying speeds during the break-in procedure is crucial for optimal performance and longevity.

Idle Running During Initial Stages

Let your nitro engine run stationary or at low throttle during the first two tanks of fuel, monitoring temperature and adjusting carb settings as needed.

Gradual Acceleration Throughout Process

- Tank 1 & 2: Keep your RC car stationary.

- Tank 3 onwards: Gradually increase RPM/throttle up to one-third open, ensuring not to exceed recommended limits.

- Cooling periods: Allow sufficient time for your nitro engine to cool down between each session.

Following these steps will ensure smooth operation and longevity of your RC car's nitro engine.

Monitoring Temperature & Tuning Adjustments

Maintaining a watchful eye on your nitro engine's temperature is an absolute must during the break-in process; make sure to employ an infrared thermometer in order to prevent any possible overheating problems.

Using Temperature Monitoring Devices

RC car engine temperature measuring (source: www.hpiracing.com)

- Infrared Thermometer: Measure the surface temperature of your cylinder head with this non-contact device.

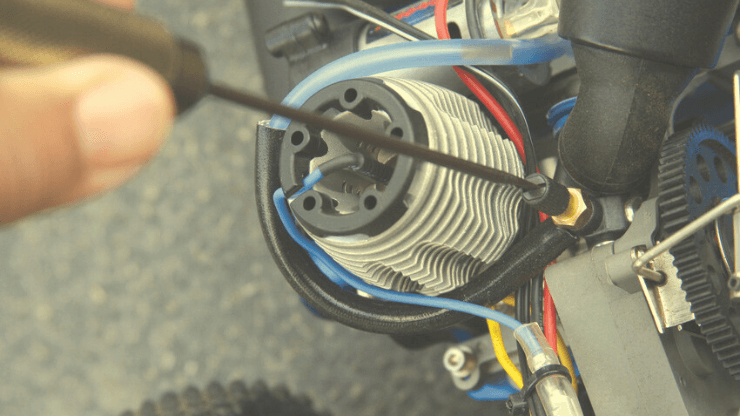

- Tuning Screwdriver: Make precise adjustments to your carburetor settings with this tool.

Carburetor Adjustment Techniques

Adjust your carb settings during the break-in period to maintain proper fuel mixture and throttle response.

- Main Needle Valve (HNV): Set it at factory specifications or slightly richer, then monitor temperatures closely while adjusting in small increments.

- Low-Speed Needle (LSN): Adjust based on idle quality and acceleration from low RPMs, turning clockwise for leaner mixtures and counter-clockwise for richer ones.

- Mixture Control Screw (MCS): Fine-tune if necessary, turning clockwise for leaner conditions and counter-clockwise for richer mixtures.

Adjusting the Carburetor

Remember: small adjustments make a big difference.

By monitoring temperature and making necessary tuning adjustments, you'll ensure smooth operation of your nitro RC car's engine during its lifespan.

Breaking In Your RC Car Engine: Methods & Techniques

Breaking in your nitro RC car engine is crucial for optimal performance and longevity, but which method should you choose?

Heat Cycling Method:

Beginner-friendly, gradually wears in the piston and cylinder head while minimizing stress on the components.

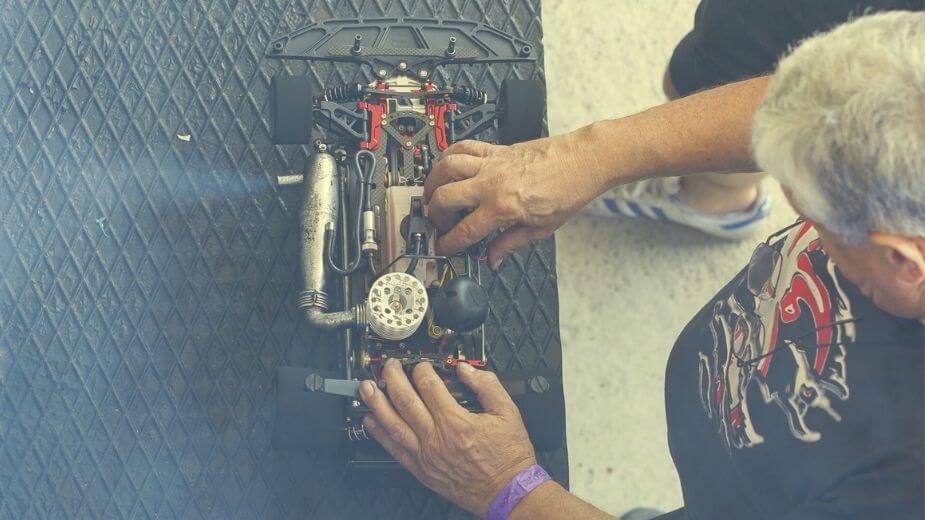

Bench Break-In Method:

RC car engine bench breaking-in

The intermediate technique gradually increases RPMs during subsequent tanks until reaching full throttle.

Running Break-In Method:

Intermediate approach, allows real-world conditions like load and traction to be factored into break-in procedure.

Advanced Break-In Techniques:

- Nitro Engine Break-In Stand: A specialized tool that securely holds your engine during break-in process while providing precise control over RPMs and temperature monitoring capabilities.

- Advanced Tuning/Monitoring Tools: Utilizing advanced devices like digital tachometers and infrared thermometers can help you fine-tune your break-in procedure for optimal results.

Choose the appropriate method based on your experience level, engine type, and personal preferences to ensure a successful nitro engine break-in. Don't forget to use high-quality nitro fuel and an electric starter to avoid damaging the engine. Happy racing.

Troubleshooting Common Break-In Problems

During the nitro engine break-in, you may face some issues that need to be addressed for a successful procedure.

- Engine stalling or struggling to start: Check linkages, fuel tubing, and adjust idle set screw. Seek expert advice if needed.

- Overheating concerns: Monitor temperature with an infrared thermometer, adjust carb settings, and ensure proper airflow around the cylinder head.

- Unusual noises and vibrations: These could indicate internal component problems that require inspection by a professional mechanic familiar with RC engines.

If you have any doubts about troubleshooting these common issues during your nitro engine break-in, seek advice from experienced racers in person or through reputable online communities like RC Doctors.

Post-Break-In Maintenance & Care

Once you've completed the nitro engine break-in, let it cool down before running it for 15-20 minutes while varying RPMs to ensure long-lasting performance reliability from your nitro RC car.

Cooling Down Period

Don't fry your engine - let it cool down after the break-in process to avoid overheating issues and ensure optimal performance.

Importance of Regular Maintenance

- Nitro Fuel: Use high-quality fuel with proper oil content as recommended by your engine manufacturer.

- Glow Plugs: Replace glow plugs periodically to keep your engine running smoothly.

- Air Filter: Clean or replace air filters regularly to maintain optimal airflow and protect against dirt entering the carburetor.

- Cylinder Head: Check cylinder head bolts for tightness every few runs to ensure they're secure but not over-tightened.

- Lubrication: Keep moving parts lubricated with appropriate oils/greases as per manufacturer recommendations.

- Tuning: Fine-tune carb settings according to temperature/humidity conditions during race days for optimal performance.

By following these maintenance tips and seeking expert advice when needed, you'll ensure that your nitro engine stays in top shape, providing reliable performance for years to come.

FAQs in Relation to How to Break in a New Rc Car Engine

How to Break in a New RC Engine

To break in a new RC engine, follow these steps:

- Ensure proper fuel flow and lubrication before starting.

- Perform an initial warm-up by starting the engine.

- Run the engine at varying speeds and throttle positions while monitoring temperature.

- Make tuning adjustments as needed.

It's essential to allow engines to cool down between runs and maintain regular check-ups after the break-in period. Here is a detailed guide on breaking in your RC car engine.

How to Break in a New Nitro RC Engine

Breaking in a new nitro RC engine involves several methods such as heat cycling, bench break-in, running break-in, or advanced techniques. Regardless of the method chosen, always ensure proper fuel flow and lubrication before starting. Gradually increase RPMs during operation while monitoring temperatures closely. Make necessary carburetor tuning adjustments throughout this process for optimal performance. Refer to this comprehensive article on breaking in Nitro engines.

What is the Break-in Period for a New Engine?

The typical break-in period for an RC car's nitro or gas-powered internal combustion engines ranges from 2-5 hours of runtime depending on manufacturer recommendations or specific model requirements. During this time frame, it's crucial to gradually increase RPMs while maintaining safe operating temperatures.

How to Break an Engine?

The term "break" in this context is likely a typo and should be "break-in." To break in an engine refers to the process of properly breaking in a new RC car engine, as described above. This involves gradually increasing RPMs while monitoring temperatures and making necessary adjustments to ensure optimal performance and longevity.

Conclusion

Want your RC car engine to last longer and perform better? Follow these crucial steps for proper break-in and maintenance.

- Prioritize safety during preparation.

- Gradually increase RPMs during the break-in process.

- Monitor temperature and make tuning adjustments as necessary.

- Properly maintain your engine after the break-in period.

There are various advanced techniques for breaking in a new RC car engine, such as the heat cycling method, but the key is to take care of your engine for improved speed and handling on the track.

By following these tips, you'll be a pro at breaking in a new RC car engine in no time!

Want to see powerful engines transform your racing experience?